FEM calculations and system analyses by means of CFD simulations

Safely planned use of valves – for greater efficiency

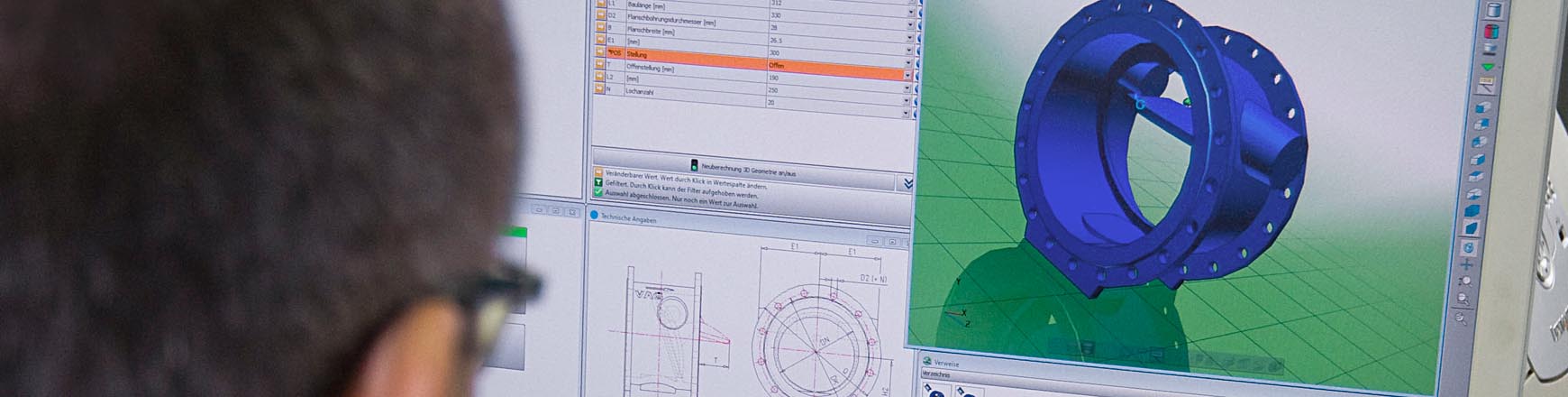

Innovative methods in valve development are required in order to keep pace with the rapid speed of technical development. The consulting team from the valve experts VAG always has the latest approaches at its disposal to make your future valves even more efficient. These include 3D valve development with the assistance of FEM strength analyses (Finite Element Method) and CFD flow simulations (Computational Fluid Dynamics). With FEM simulation, for example, the optimal distribution of force to the component or the stress behaviour of a flow-optimised butterfly disc of a turbine inlet valve can be determined and visualised. FEM also makes it possible to adapt the calculation models to the real load conditions, making it possible to carry out an exact strength analysis even in the case of complex stresses.

In addition to that, the CFD analysis assists with the examination of the flow behaviour when a valve is actuated. Through intensive further development on the valve model it was possible, for example, with the new VAG EKN® H300 Butterfly Valve to achieve an improvement in the flow resistance by about 20% due to a reduction in the formation of turbulences. Therefore, both methods guarantee not only the reliable control of every operating state that occurs, but also a significant increase in the efficiency of the entire plant.