VAG double-offset butterfly valves

Efficiency up to the minutest detail

Butterfly valves made by VAG have proven themselves world-wide under the roughest operating conditions. Today’s water management would no longer be conceivable without them. Besides lower flow resistance, their hydrodynamically optimised design significantly reduces the risk of damage by cavitation even at increased flow velocities.

Our highlight: VAG EKN® H Butterfly Valves

The EKN-H Butterfly Valve, a double-offset, resilient-seated flanged butterfly valve, sets new standards in the valve industry. It is suitable for the most stringent requirements and is precisely adapted to any customer needs. Its hydrodynamic design combines a long service life with energy efficiency thanks to its patented disk, its bearing that does not come into contact with the medium and a wear-resistant, corrosion- and infiltration-proof seat ensured by a weld overlay. Compared to a conventional butterfly valve, the operation of a VAG EKN® H offers a savings potential of up to 59% of CO2.

Efficiency and sustainability redefined.

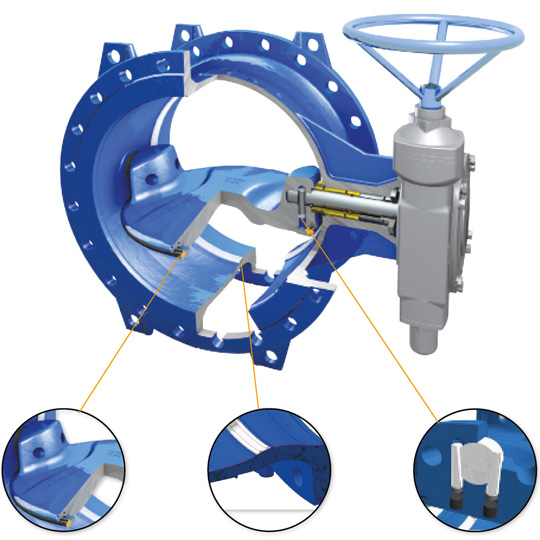

What makes this valve so special?

- Patented hydrodynamic disk design: Ensures minimal pressure loss and an increased service life through the reduction of turbulences and cavitation. Considerable energy savings are possible thanks to its reduced flow resistance.

- Patented seat geometry: The high-alloy weld overlay provides reliable protection against corrosion and infiltration of the seat. The flat and specially processed seat design ensures permanently low operating forces.

- Patented wedge pin connection: Ensures the permanently backlash-free connection between shaft and disk as well as a reliable and permanent transmission of forces for a maximum service life.

- Bearing system: The bronze bearing and the double O-ring seal ensure effective corrosion protection of the bearing. Thus, the bearing system is protected 100% from the medium

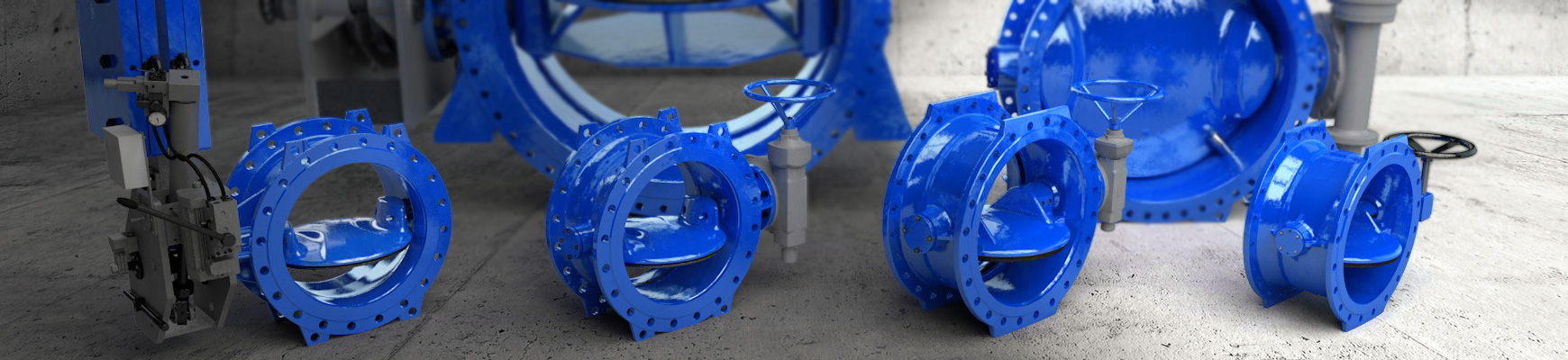

Various platforms for diverse applications

Thanks to their high reliability of operation, their robust design and corrosion resistance, double-offset butterfly valves made by VAG can be used in almost any application, both in buried installations and in plant construction. Thanks to their great variety of materials and coatings, VAG EKN® Butterfly Valves cover a wide range of applications.

M-Series for medium requirements

Proven VAG quality with fully encapsulated bearing for even better corrosion protection and featuring a wear-resistant valve seat. An automatic sealing system that operates independent of the flow and is equipped with a special profiled seal resists even high gap velocities.

H-Series for maximum performance

This series meets the highest requirements in water treatment, water distribution, in power plants and in dams. Its saves energy costs due to its innovative design featuring a hydrodynamic disk, an enlarged inner diameter and patented pressure compensation channels. Thanks to their special design, butterfly valves of the H-Series minimise pressure losses and turbulences in the outlet area. Their maximum corrosion protection ensures an extremely long service life even under the most demanding operating conditions.

Depending on the type and model, VAG EKN® Butterfly Valves are suitable for use with the following media:

- Drinking water

- Raw water

- Cooling water

- River water

- Service water

- Sea water

- Aggressive waters

- Waste water (some kinds/pre-treated)

London‘s growing population and increasing temperatures are putting it at risk of drought. According…

The VAG EKN® Butterfly Valve in fabricated steel design was 100% leak-tight, worked troublefree and…