VAG Installation at Cherry dam

Removal of Existing 66-inch Hollow Jet valves and actuation systems.

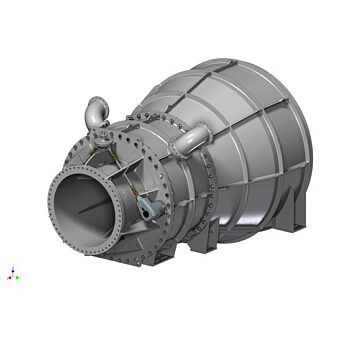

Installation of two (2) new 66-inch Howell-Bunger (Fixed Cone Valves) complete with discharge hood, support bracing, and electric actuation system. Demolition of existing IFR system and removal of associated equipment.

Cherry Lake (also known as Lake Lloyd) is an artificial lake in the Stanislaus National Forest of Tuolumne County, California USA about 25 miles (40 km) east of the city of Sonora. It is at an elevation of 4,700 feet (1,433 m) on the western side of the Sierra Nevada, and lies just outside the western boundary of Yosemite National Park. The lake has a capacity of 273,500 acre·ft (337,400,000 m3) and is formed by Cherry Valley Dam on Cherry Creek.

The dam is composed of earth and rock-fill and has a height of 315 ft (96 m) above the original streambed. It was built by San Francisco City and County and the Modesto Irrigation District and Turlock Irrigation District. It was completed in 1956. The lake stores water for the Hetch Hetchy Project, which supplies drinking water to the San Francisco Bay Area, Modesto and Turlock districts. Recreation available at the lake includes, boating, skiing, swimming and fishing. Human contact with the water is allowed because the water must be filtered anyway. Water from the lake powers the Dion R. Holm Power Plant, a 165 MW hydroelectric facility.

San Francisco Public Utilities Commission (SFPUC) announced the design of project to replace the bottom outlet valves in September of 2013. VAG offered specification and design advice and was listed in the specification for the project which bid 3 years later in 2016. Due to the large greater San Francisco population served, earthquake zones and critical water storage in the California High Sierra Mountains, SFPUC was in need of a high-quality valve. VAG´s technical solution included the updated and innovative KSSplus design. After final review VAG was selected for the supply of 2 pcs. VAG 66” KSSplus Howell-Bunger®Valves completely manufactured from stainless steel with 100” venting system and 145” hood.

SFPUC is a customer with rigorous requirements including 13 separate witness inspections which is nearly unheard of for QA/QC measures. Upon completion of the manufacturing and final witness inspection, SFPUC communicated that the VAG valve was a very good-looking valve. After commissioning the final customer was deeply impressed about the reliable function of the VAG products which are still working as expected.