VAG EKN® H Butterfly Valve - Efficiency and Sustainability Redefined

Butterfly valves have been in use for many decades in various configurations and have proven their worth worldwide under a wide variety of operating conditions. Without them, today's water management would not be imaginable: In municipal water supply systems, in dams, in transport pipelines, in cooling systems of power plants, or in industry, butterfly valves are used wherever water is stored, conveyed, treated and distributed.

Let's travel back to 1978: a historic year, not only because of the first German astronaut flying into space, but VAG introduces its first butterfly valve of the new EKN series. The “ExzenterKlappenNormprogramm” (in short: EKN for eccentric butterfly valve standard program) is born. The double-offset geometry reduces the forces required for opening and closing and extends the service life thanks to minimized wear and tear. More than 50 years of experience in the manufacture and further development of butterfly valves later, the VAG EKN® series is now in use worldwide and is one of the most important and renowned products in the VAG family.

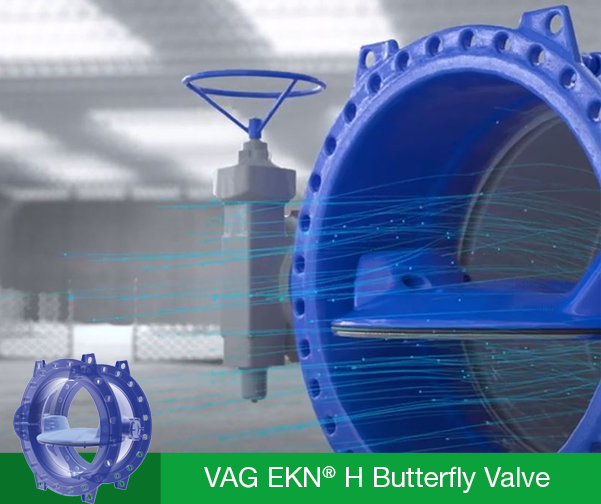

With the VAG EKN® H, the latest model in the VAG EKN® series is now available.

In various applications, such as in pumping stations or as turbine inlet valves, an energy-efficient design of the butterfly valve is of high importance as the flow resistance occurring in the pipeline is directly related to the energy costs. The more flow-efficient the valve is designed, the less resistance is created in the system. The VAG EKN® H butterfly valve has set new standards here. With its patented hydrodynamic disc and extended inner diameter, it reduces flow resistance by up to 59% compared to conventional butterfly valves - and such sustainably saves energy and emissions.

In addition to lower flow resistance, the hydrodynamically optimized design of the butterfly valve offers further advantages: the risk of cavitation damage at increased flow velocities is significantly reduced. Likewise, the highly laminar flow allows a significantly reduced distance to downstream installations in the pipeline. Due to lower flow turbulence, vibration is also minimized, thus increasing the service life of the butterfly valves. The low pressure loss reduces the required performance of the pump. This even allows the selection of smaller pumps and the realization of further energy saving potentials.

Another VAG specialty: the wear and corrosion resistant body seat of the VAG EKN® H with extended seat geometry and high-precision machining, thanks to built-up welding, ensures maximum reliability of the entire sealing system with simultaneously low actuating torques. Both the pull-out-proof sealing system on the valve disc and the bronze bearing with double O-ring sealing ensure effective corrosion protection of the entire valve. The bearing system is 100% protected from the medium. In addition, our new wedge pin connection ensures a permanently backlash-free connection of shaft and disc as well as a safe and permanent power transmission. All these are further measures for maximum service life and highest availability in operation.

Efficiency, sustainability and durability characterize the VAG EKN® H - the perfect butterfly valve.

Product details: VAG EKN® H Butterfly Valve

Animation

VAG product animation of EKN® H Butterfly Valve: Energy-efficient, double-offset flanged butterfly valve (resilient-seated) suitable for the highest requirements, equipped with a patented hydro-dynamic disk, enlarged inner diameter and patented pressure compensation channels.

-

EKN-H_Flyer_Digital_EN.pdf

Stáhnout